Implementing flexible milking

20 min read

Information on this page has been gathered through experiments and from farmers already utilising flexible milking. Farmers commonly decide to implement flexible milking to provide more flexibility and work-life balance for them and their team. This page aims to help farmers and advisors with successful implementation of flexible milking strategies, it provides experiences and information on a range of factors from choosing an interval, rosters, grazing, somatic cell count, milk cooling, tanker scheduling, and more.

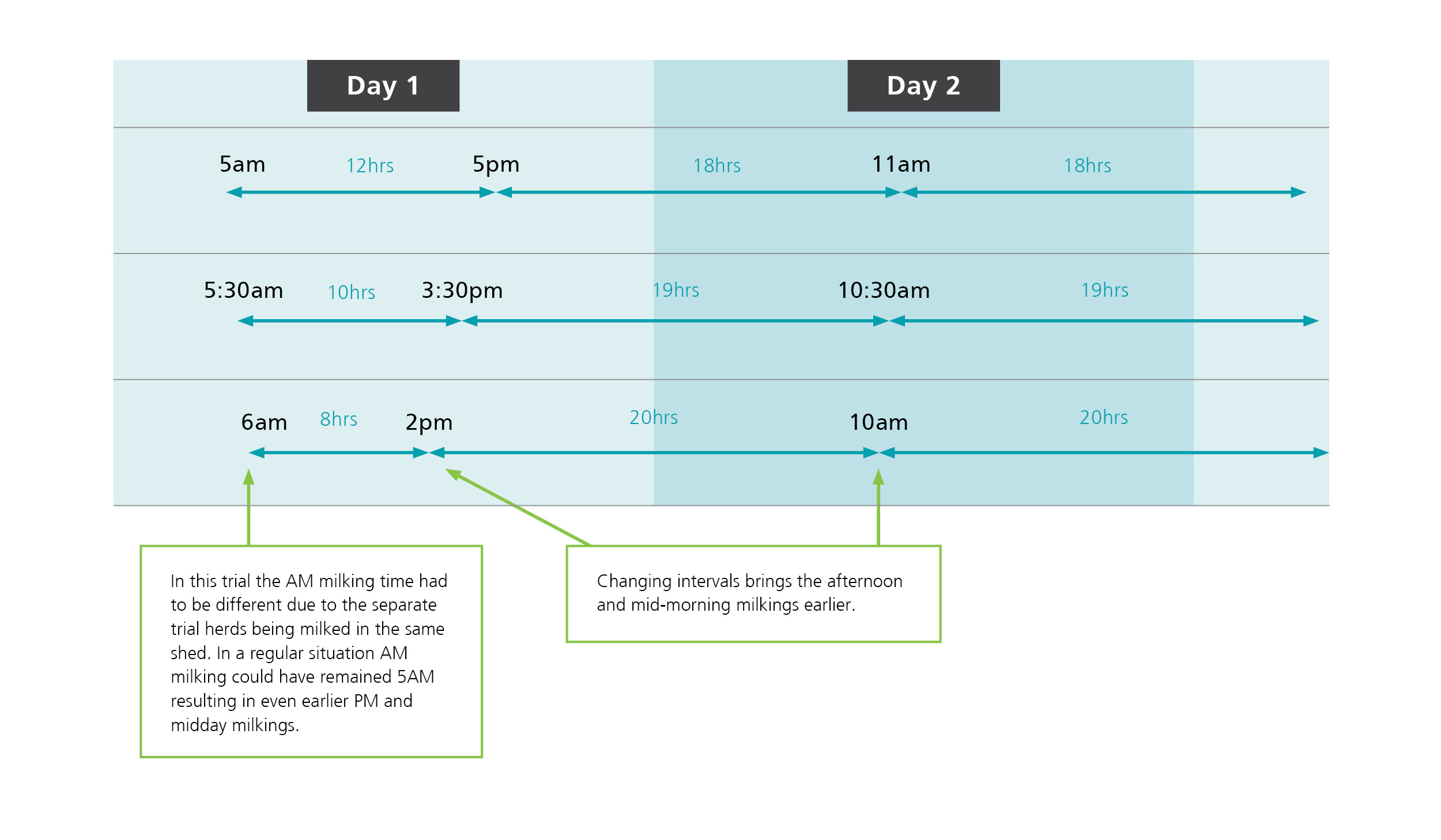

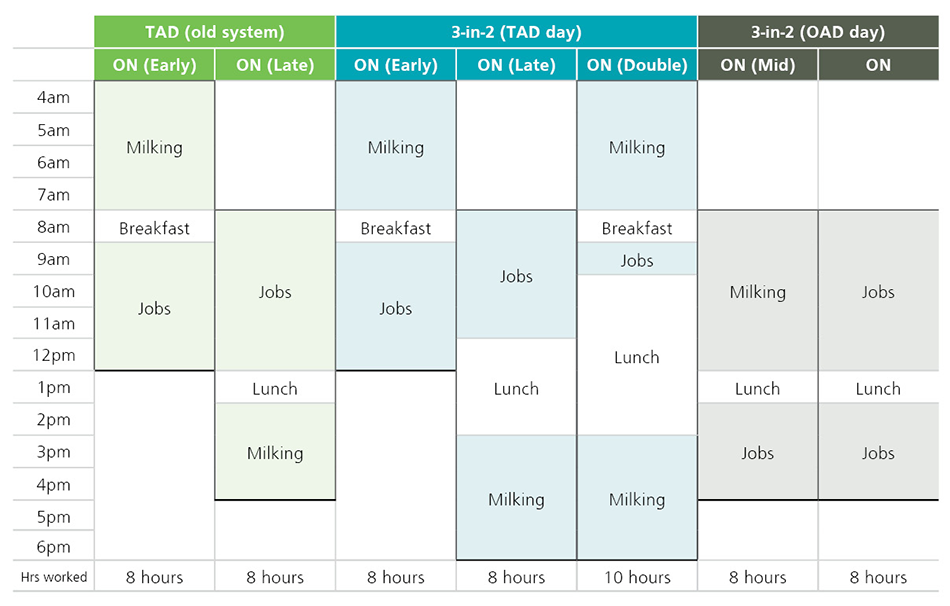

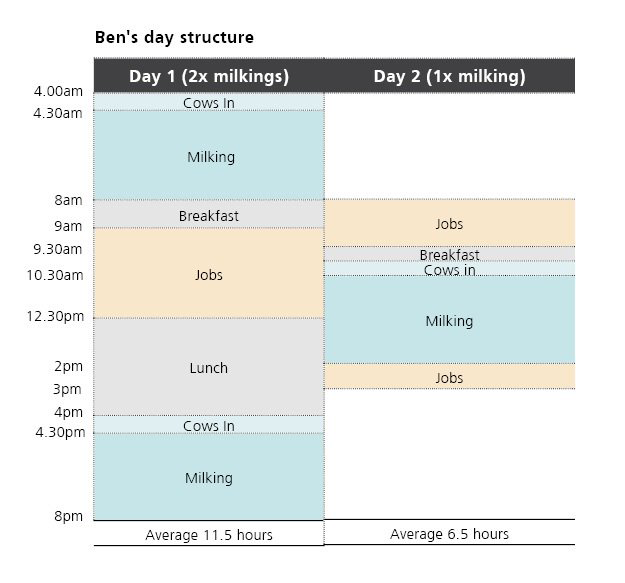

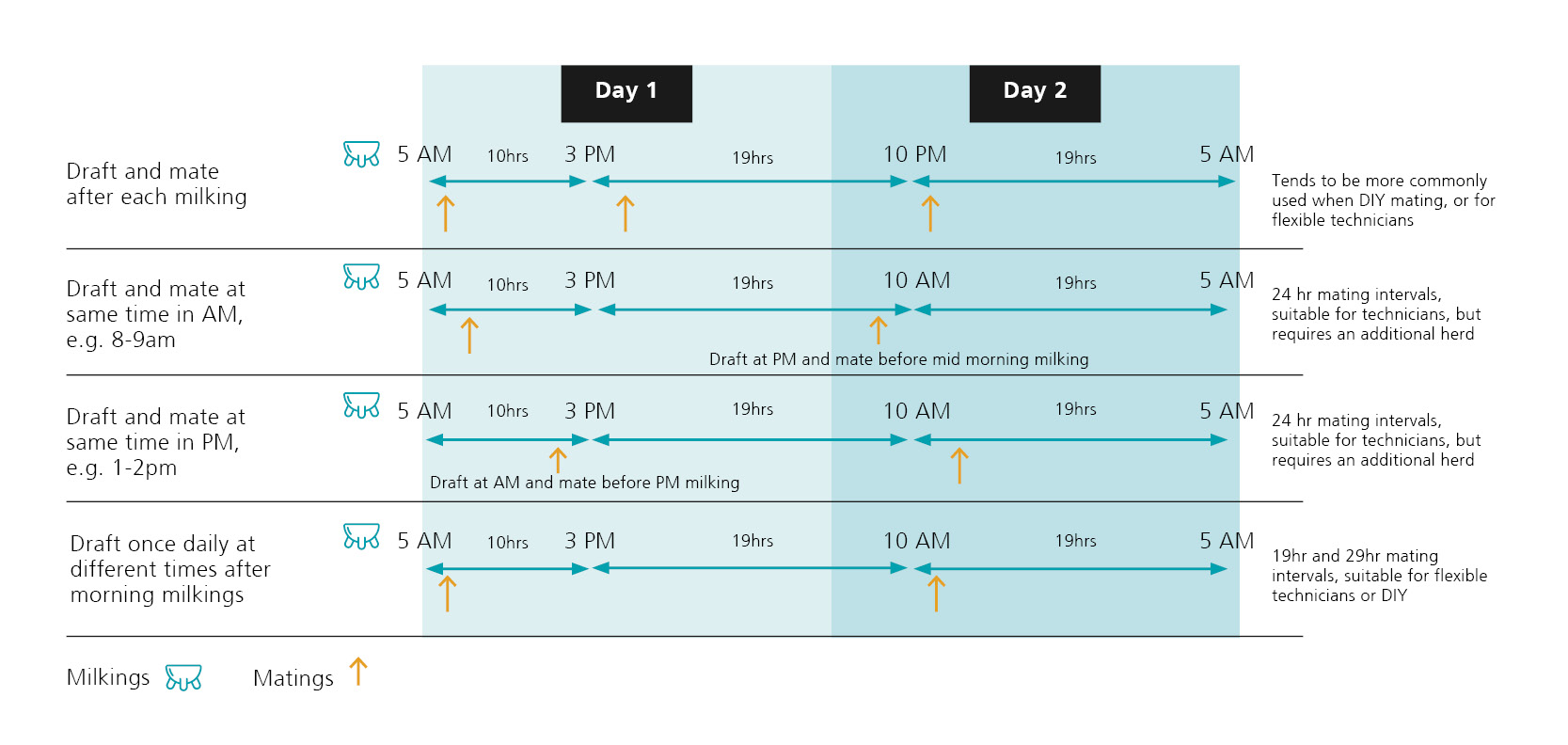

Deciding how to space the three milkings over the two days will have implications for the attractiveness of the system to the people on farm.

With the help of the information and the milking time planner below, work with your team to find a suitable routine and maximise the benefits.

Use the Milking time planner to estimate/assess the effect of different flexible milking times on milking intervals, weekly schedules and production.

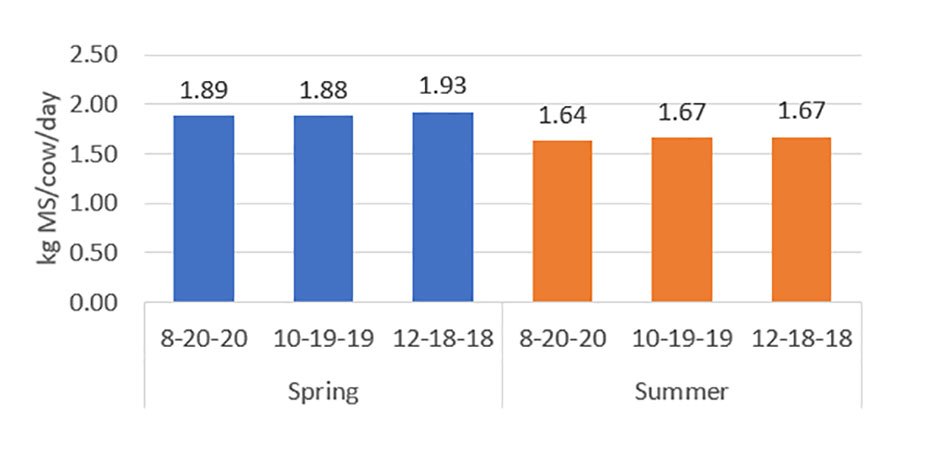

Trials found no statistical difference in group average production when milked at a 12-18-18, 10-19-19, or an 8-20-20 interval. In practice there is likely to be a small trade-off (see explanation under Interval Experiment).

The data below should give farmers confidence to select the milking times that are most suitable to their farm and team, particularly if flexibility is a key reason for adopting flexible milking.

For examples of how this has been applied in practice, check out the info on our 2020/21 pilot farmers. These farmers have adapted the times to suit them, including:

In 2020/21 DairyNZ ran two six-week experiments to determine if there was any impact on the timing of milkings on production levels during peak and mid-lactation.

All herds contained 40 cows and were grazed side by side in the same paddock, separated by an electric fence.

Changing these intervals brings the afternoon and mid-morning milkings earlier. Both attractive changes for many people.

Statistically, there were no differences in the kilograms of milksolids per cow per day produced between each of the 3-in-2 herds.

The trials utilised two control herds (OAD and TAD) to explore whether there were differences in milk production that were too small to detect in the previous analysis.

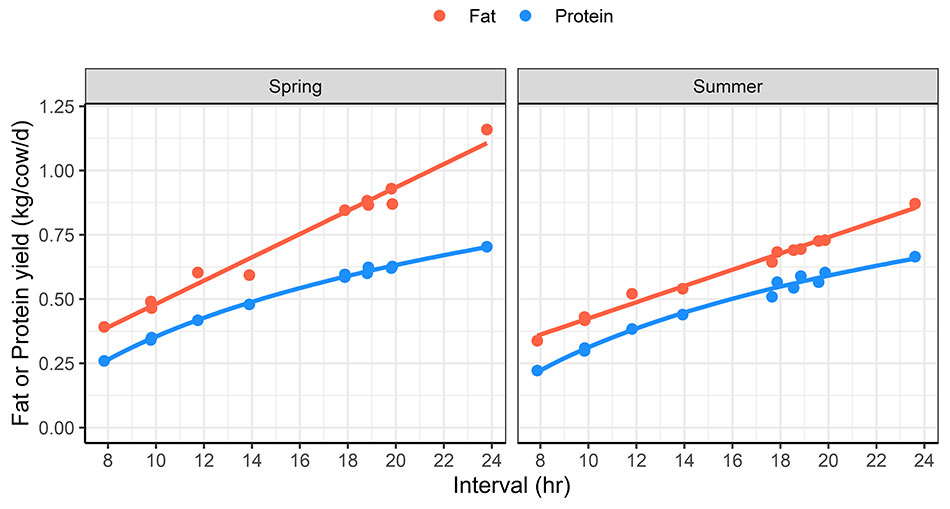

Each AM, PM and mid-morning milking for all milking frequencies were plotted separately (see figure). The overall trends, linear for fat and curvilinear for protein, are supported by previous research and match those observed in our 2019/20 farmlet study.

AM, PM and mid-morning milking for all milking frequencies.

These trends can be used to estimate the scale of underlying differences between 3-in-2 intervals.

This research shows us that, although there may be small biological differences to using longer milking intervals, these differences were too small to detect at the herd level. Therefore, a change in milksolids under more attractive 3-in-2 milking times, particularly 10-19-19 relative to 16-16-16 or 12-18-18, are unlikely to be noticeable on commercial farms, particularly if the improved interval results in a more engaged farm team with less fatigue and improved farm management.

Adapting flexible milking times to suit your weekly schedule

As the popularity of 3-in-2 milking increases, it is clear there is no one-size fits all approach, hence the term 'flexible milking'.

This allows you flexibility in choosing when you want to milk, based on your values and situation.

The following table outlines several examples that we have seen on farms throughout New Zealand and is by no means an exhaustive list. Note some of these intervals may affect milk production.

Under flexible milking systems, milking times on the day with one milking are generally timed to be halfway between the previous milking and the next milking. E.g. for 13-in-7, Sunday 10am is 19 hours after Saturday 3pm and 19 hours before 5am Monday.

| TAD | 3-in-2 | Variable interval | OAD | |||

| Schedule | 10-14 | 10-19-19 | 13-in-7 | 12-in-7 | 10-in-7 | 24 |

| Monday | 5am:3pm | 5am:5pm | 5am:3pm | 5am:3pm | 5am:3pm | 7am |

| Tuesday | 5am:3pm | 11am | 5am:3pm | 5am:3pm | 10am | 7am |

| Wednesday | 5am:3pm | 5am:5pm | 5am:3pm | 10am | 5am:3pm | 7am |

| Thursday | 5am:3pm | 11am | 5am:3pm | 5am:3pm | 10am | 7am |

| Friday | 5am:3pm | 5am:5pm | 5am:3pm | 5am:3pm | 5am:3pm | 7am |

| Saturday | 5am:3pm | 11am | 5am:3pm | 5am:3pm | 10am | 7am |

| Sunday | 5am:3pm | 5am:5pm | 10am | 10am | 7:30am | 7am |

| Milkings in a fortnight |

28 | 21 | 26 | 24 | 20 | 14 |

| Reduction from TAD |

25% | 7% | 14% | 29% | 50% | |

Rosters and managing staff time on a flexible milking schedule

One of the top 3 reasons that farmers make the move to flexible milking is for their people – mainly to help reduce staff hours, increase flexibility and work/life balance for them and their staff, and improve staff retention.

Talk with your team and come up with a plan that is desirable for everyone, whether that be a sleep-in, earlier finishes, or a bit of both. Working with the farm team on the best way to structure the day is important to ensure that they can benefit from the change without affecting other non-milking jobs that are important for the farm. Reducing day length will likely benefit farm efficiency through a more motivated team (work-life balance) and improved rest time, resulting in fewer mistakes.

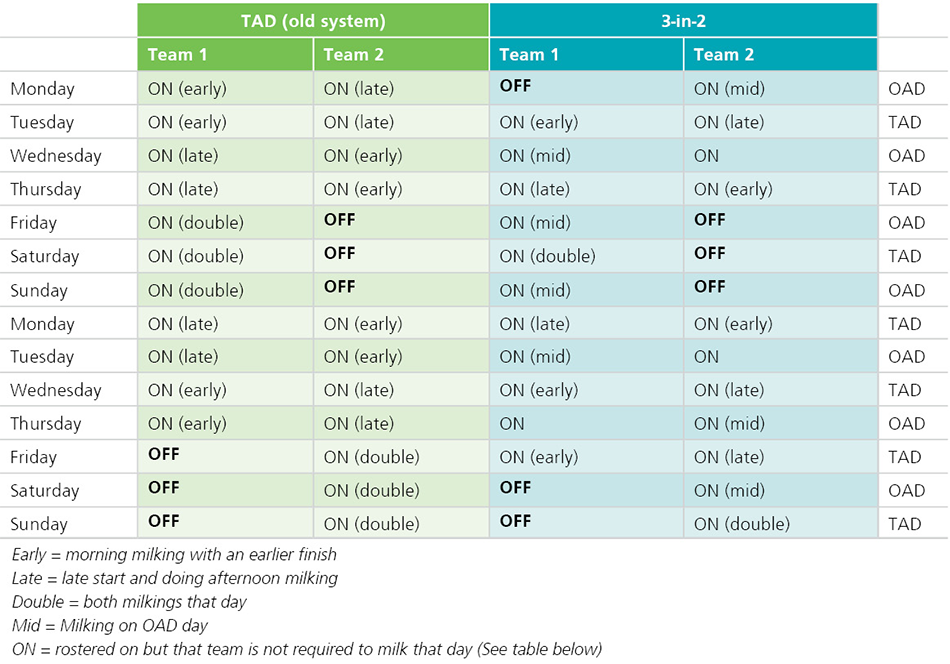

Each farm is different in terms of staff numbers, responsibilities, milking times etc. so there is no one-size-fits-all approach for how to best manage your roster. However, we have included some examples of how farms already implementing 3-in-2 around the country have organised their roster and/or day to day management of time to create flexibility or reduce overall hours worked. This may help to spark ideas for how to best implement it on your farm to maximise the benefits of using a flexible milking approach.

With milkings occurring at different times, a further opportunity may be to secure relief milking or part time staff from alternative sources – such as those that can work outside of 9-5, or around school hours etc. In some situations this could result in fewer full-time staff, replaced by more part-time staff.

If you are thinking about changing your roster structure, or want to find out if your current roster is the best fit for your farm, find more about selecting rosters.

Case study - Angela Reid, Southland

1250 Cows, 6 Staff

Angela’s system:

“We found that we had to stagger the days off when we moved to 3in2, with one team taking Fri-Sun, and the other team taking Sat-Mon the following weekend, to ensure that it was fair with 2 TAD and 1 OAD on each set of days off (Table 1).”

Case study - Ben Wilson, Kirwee

710 cows, 4 staff

Roster:

Ben runs a 7-2, 7-2, 7-3 roster year-round, which has stayed the same between TAD and 3-in-2 milking. The team uses alternating long and short days when milking 3-in-2. This means they can get more jobs done on the two-milking day, allowing for a shorter day on the one-milking day, where the aim is to do only the basics unless something urgent comes up.

Ben says it’s still important to give the team a long lunch break on the longer days, so they get a rest before returning for afternoon/evening milking.

Flexible Milking approaches allow farmers to think outside the square

There are a vast number of ways to take advantage of the flexibility that 3-in-2 milking offers. Below we share ideas to illustrate how some creative thinking can maximise the benefits for people on-farm.

When considering how to make the most of flexible milking, take the time to think about what hours and days of the week work well for your farm and staff. Here are a few examples:

Hear from Canterbury farmer John Totty. Managing grazing on 10-in-7.

Video 0:55 min

Hear from Taranaki farmers Daryl & Karyn. Most challenging aspects of 3-in-2 milking.

Flexible milking can be used to extend the grazing rotation in mid lactation:

| Number of paddocks in farm | 40 | 44 | 48 |

| Rotation for 1 paddock/milking (TAD) | 20 | 22 | 24 |

| Rotation for 1 paddock/milking (3-in-2) | 27 | 29 | 32 |

| Rotation for 1.33 paddocks/milking (3-in-2) | 20 | 22 | 24 |

| Rotation for 1.5 paddocks/milking (3-in-2) | 18 | 20 | 21 |

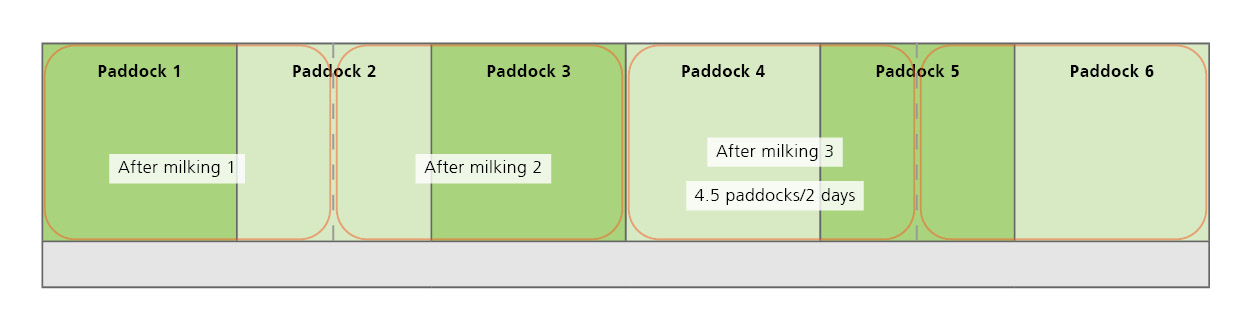

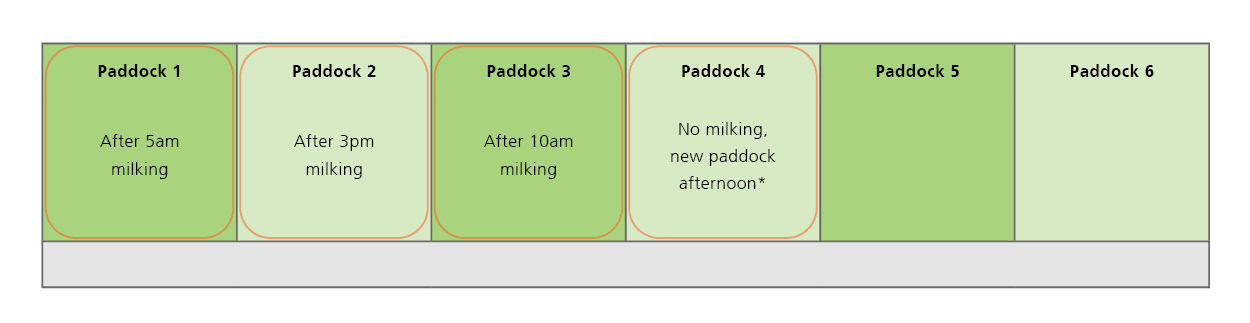

As shown in the first row (TAD), many farmers offer a paddock after each milking.

If you continue to use one paddock/milking on 3-in-2 system, you will automatically extend the rotation. At some times of the year this can be ideal.

At times when you would like to keep the same rotation length, e.g., using full-season 3-in-2. Keeping the same round is more difficult as you would then need to be giving 1.33 paddocks after each milking.

Figure 1: One & a half paddocks/milking

Figure 2: One paddock/milking and an afternoon shift on the days with one milking

Changes to farm costs as a result of milking 3-in-2 will be highly farm-specific, so it is advisable to prepare a budget.

Below is an example of pilot farmer, John Totty, before and during flexible milking farm information and results.

| 2019/20 | 2019/20 District average* | 2020/21 | 2020/21 District average* | |

| Farm milking schedule | 3 weeks OAD at calving then TAD TAD milking times 5.30am and 2.30pm |

3 weeks OAD at calving then 10-in-7 Mon, Weds, Fri 5.30am & 2:30pm. Tues, Thurs, Sat 10am, Sun 8am |

||

| Peak Cows Milked | 900 | 1137 | 994 | 1107 |

| Stocking rate | 2.9 | 3.7 | 3.2 | 3.7 |

| kgMS/cow | 377 | 489 | 378 | 479 |

| kgMS/ha | 1801 | 1212 | 1795 | |

| 10-day peak per cow (kgMS/cow/day) | 1.57 | 2.19 | 1.51 | 2.15 |

| Imported Feed (kgDM/cow) | 279 | 760 | 80 | 635 |

| kgN applied/ha | 190 | 217 | 180 | 204 |

| 6wk ICR | 65% | 67% | 75% | 67% |

| Not-in-calf rate | 13% | 17% | 11% | 16% |

| FWE ($/kgMS) | $4.90 | $4.38 | $4.69 | $4.37 |

| Profit/ha | $2271 | $4044 | $3641 | $4865 |

| Operating profit margin | 26% | 32% | 36% | 36% |

*Ashburton district or Canterbury average, which are typically irrigated. John’s property is a dryland farm.

John has updated his milking times for the 21/22 season, see the milking times chart for his new schedule.

There are some obvious cost savings in the dairy with 25 percent fewer milkings. For example detergent, electricity and rubberware are all likely to decrease. However, combined shed expenses are unlikely to reduce by 25% for the time you are using 3-in-2 because there is more milk to harvest at the remaining milkings which will offset some of the potential savings.

Whether 3-in-2 results in a decrease in labour costs will be highly farm specific. With the exception of large farms it is unlikely to change the number of full-time staff required. Costs may be reduced if you pay hourly or are able to reduce the need for relief milkers due to different milking intervals.

With milkings occurring at different times, a further opportunity may be to secure relief milking or part time staff from alternative sources – such as those that can work outside of 9-5, or around school hours etc. In some situations this could result in fewer full-time staff, replaced by more part-time staff.

The use of flexible milking intervals such as 3-in-2 provides an excellent opportunity to reduce hours of work and increase flexibility for people on farm. Ask your team and come up with a plan that is desirable for everyone, whether that be a sleep-in, earlier finishes, or a bit of both. Working with the farm team on the best way to structure the day is important to ensure that they can benefit from the change without affecting other non-milking jobs that are important for the farm. Reducing day length will likely benefit farm efficiency through a more motivated team (work-life balance) and improved rest time, resulting in fewer mistakes.

As covered above, the most frequently discussed costs are dairy shed expenses and labour. For more information on potential cost savings as a result of farm system changes see the flexible milking farmlet results, or read below the results of a modelling study over 5 seasons using different milking intervals.

In another attempt to answer the question on when in the season to use reduced milking frequencies we designed a modelling study to evaluate the economic implications of implementing combinations of TAD, 3-in-2, and OAD across a lactation season on a typical Waikato farm.

Results for the selected scenarios over five consecutive seasons. Averages with percentage change from full season twice-a-day (TAD) in brackets

(% change has been calculated prior to values being rounded and then rounded to nearest %)

| Full-season TAD |

Full-season 3-in-2 |

3-in-2 Jul-Aug and Feb-Apr |

3-in-2 Feb-Apr |

|

| Pasture yield (t DM/ha) | 15.8 | 15.7 (-1) | 15.8 (0) | 15.7 (0) |

| Pasture eaten (t DM/ha) | 15.1 | 14.9 (-2) | 15 (-1) | 15.1 (-1) |

| Supplements fed (kg DM/cow) | 1316 | 1259 (-4) | 1298 (-1) | 1302 (-1) |

| Milksolids (kg/cow) | 407 | 389 (-5) | 397 (-3) | 403 (-1) |

| Milksolids (kg/ha) | 1315 | 1256 (-4) | 1281 (-3) | 1303 (-1) |

| Mean days in milk | 275 | 277 (1) | 276 (0) | 276 (0) |

| BCS at calving | 4.5 | 4.8 (7) | 4.6 (4) | 4.6 (2) |

| Days to 50% calved | 17.4 | 16.4 (-6) | 17.4 (0) | 17.2 (-1) |

| 6-week in calf rate (%) | 76.2 | 78.6 (3) | 77 (1) | 76 (0) |

| Final not-in-calf rate (%) | 8.8 | 8.6 (-2) | 8 (-9) | 8.2 (-7) |

| Farm working expenses ($/ha) | 5717 | 5597 (-2) | 5660 (-1) | 5662 (-1) |

| Farm dairy ($/ha) | 74 | 63 (-15) | 68 (-8) | 68 (-8) |

| Electricity ($/ha) | 140 | 119 (-15) | 130 (-7) | 130 (-7) |

| Operating profit ($/ha) | 2226 | 2033 (-9) | 2091 (-6) | 2198 (-1) |

| Greenhouse gas emissions (kg CO2-eq/ha) |

17139 | 16889 (-1.5) | 17021 (-1) | 17004 (-1) |

Milking 3-in-2 across the whole season reduced average operating profit by 9% compared with TAD.

Full-season 3-in-2:

The large difference in the volume of milk between milkings can create issues with milk cooling, however, the specific reasons, and therefore best solutions, may differ between farms.

Bacteria in raw milk grow rapidly above 6˚C so NZCP1 states that raw milk must be:

An expensive replacement or upgrade is not always required to solve the issues some farmers have experienced.

Two examples are listed below, that have been experienced by pilot farmers during the 2020/21 season:

Example 1: Failing to remain within blended milk temperature requirements (point 3)

The 10-19-19 hr farm was on daytime daily milk collection.

Example 2: Struggling to cool milk in the required timeframe (point 1)

The farm had historically struggled with milk cooling over the summer months, so in winter 2020 upgraded his milk cooling unit, as per refrigeration company specifications, to help address this issue.

It’s worth getting to the bottom of the issue specific to your farm with your milk processor and refrigeration supplier and identifying all the options available. Often there are multiple options available, which differ considerably in cost and effort to implement. Monitor your milk telemetry results and look for the most cost-effective option. In some cases, there will be opportunity to improve the effectiveness of the primary cooling at little cost.

This question is often asked in mid-lactation. The answer will depend on what you are trying to achieve by changing milking frequency.

Is the goal to reduce milking hours for staff and reduce walking for the herd?

Is the goal around improving the body condition of lighter cows?

Managing the mating period using 3-in-2

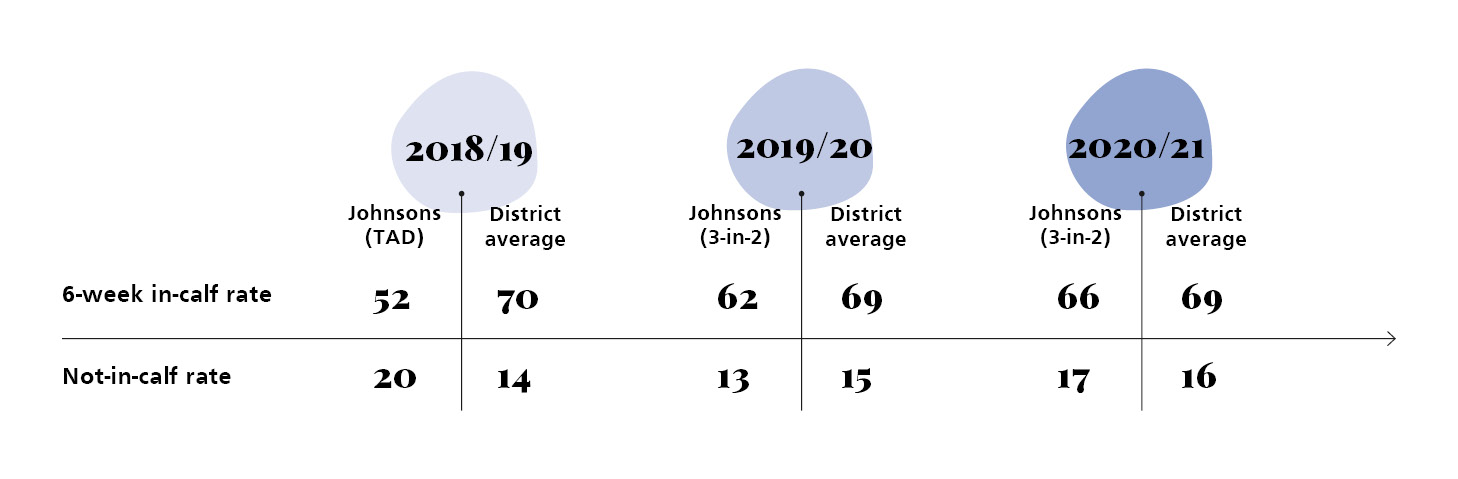

Several farmers who have been using full-season 3-in-2 for multiple years have given us their mating plans – see below. Depending on the system you choose for your farm, and your previous experience and results, your results may differ.

Figure 1: Milking and mating times used by pilot farms

Please note that these are working examples from the farmers that we spoke to. When creating your own plans, be sure to consider the following:

Under all the scenarios below, the farmers found their results to be similar, if not better than when they used a standard milking and mating system. Depending on the system you choose for your farm, and your previous experience and results, your results may differ.

Figure 2. Mating options.

Table 1: Reproduction results experienced by Taranaki pilot farmers. Karyn and Daryl used the first method - drafted and mated after ever milking.

Research in NZ has shown that non-return rates of animals detected in heat at the previous PM milking or the AM milking directly before AI under OAD mating systems were not significantly different, suggesting that there may be some flexibility in the time of AI in relation to standing heat.

For flexible milking intervals, it is possible that an improvement from energy status and BCS of the cows may offset some timing issues if cows are being mated with long intervals between standing heat and ovulation (e.g. >28 hours), resulting in similar reproductive outcomes. Talk to your technician or herd improvement representative to help select the best plan for your farm situation.

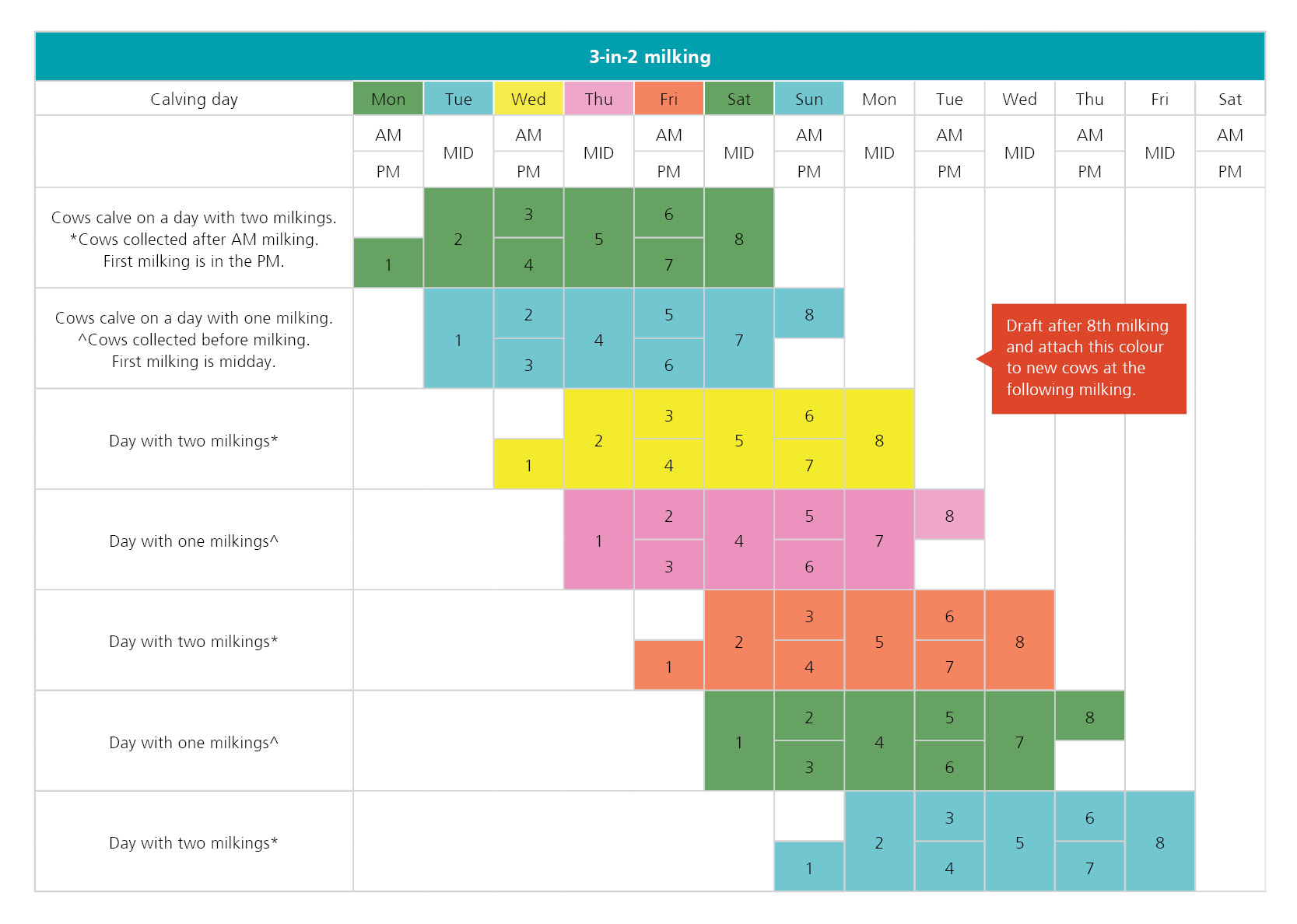

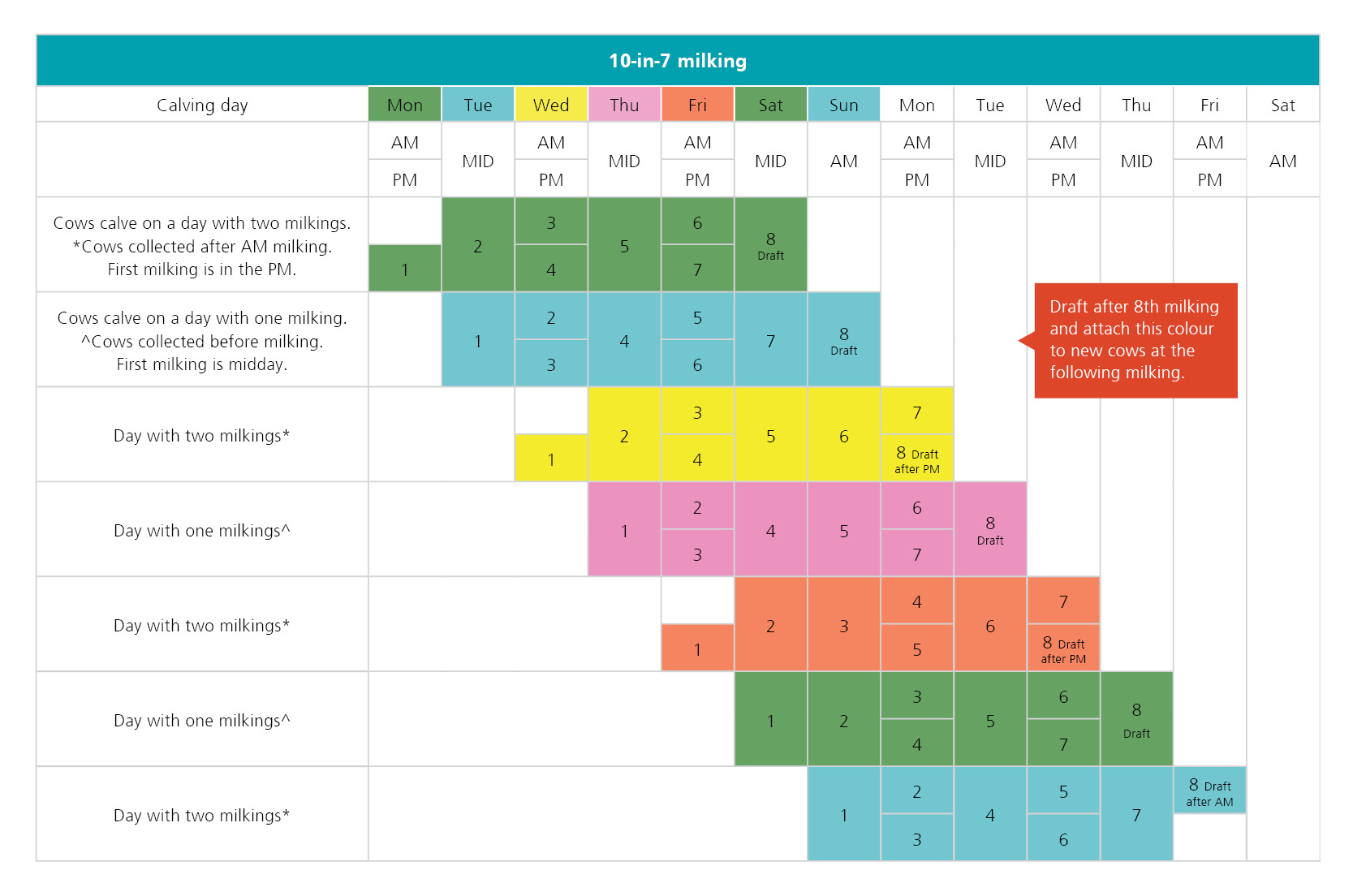

Managing the colostrum mob with flexible milking

Many farms milk colostrum cows OAD to help with workload during a busy calving period, the aim is to select times that will make the intervals as close to 24 hours as possible.

Here’s how one of the pilot farmers plans to manage this while milking 3-in-2:

The aim is to select times that will make the intervals as close to 24 hours as possible, the above example is 22 and 26 hours.

To ensure that colostrum doesn’t get into the supply milk when milking before the main herd, NZCP1 states that milking equipment must be hot washed after milking to ensure that any remaining residue is effectively removed.

Alternatively, other farmers continue to milk their colostrums at every milking when on 3in2. Typically, TAD farmers use a 4-colour tape system to identify when cows have reached their 8 milkings. Under a 3-in-2 system, this would need to be tweaked. See the below table for an example 5-colour option that will help to meet the 8-milking standard - modify to suit your needs.

This scenario assumes that calved cows are only brought into the colostrum mob once a day.

10-in-7 milking

Adapt this to your system to ensure your colostrum’s are milked 8 times before entering the vat.

Managing somatic cell count and tanker scheduling

Top tips:

High SCC milking

Many farmers that were interviewed had expected the longest milking interval to result in the highest Somatic Cell Count (SCC), due to pressure in the udder, and the previous knowledge around SCC increasing when going on OAD.

However, it is the shortest milking interval that tends to have the highest SCC.

This is due to there being a lower volume of milk in which to dilute a similar number of somatic cells, generating a higher milk SCC. A bulk tank containing only milk collected after a short interval will have a higher bulk milk SCC.

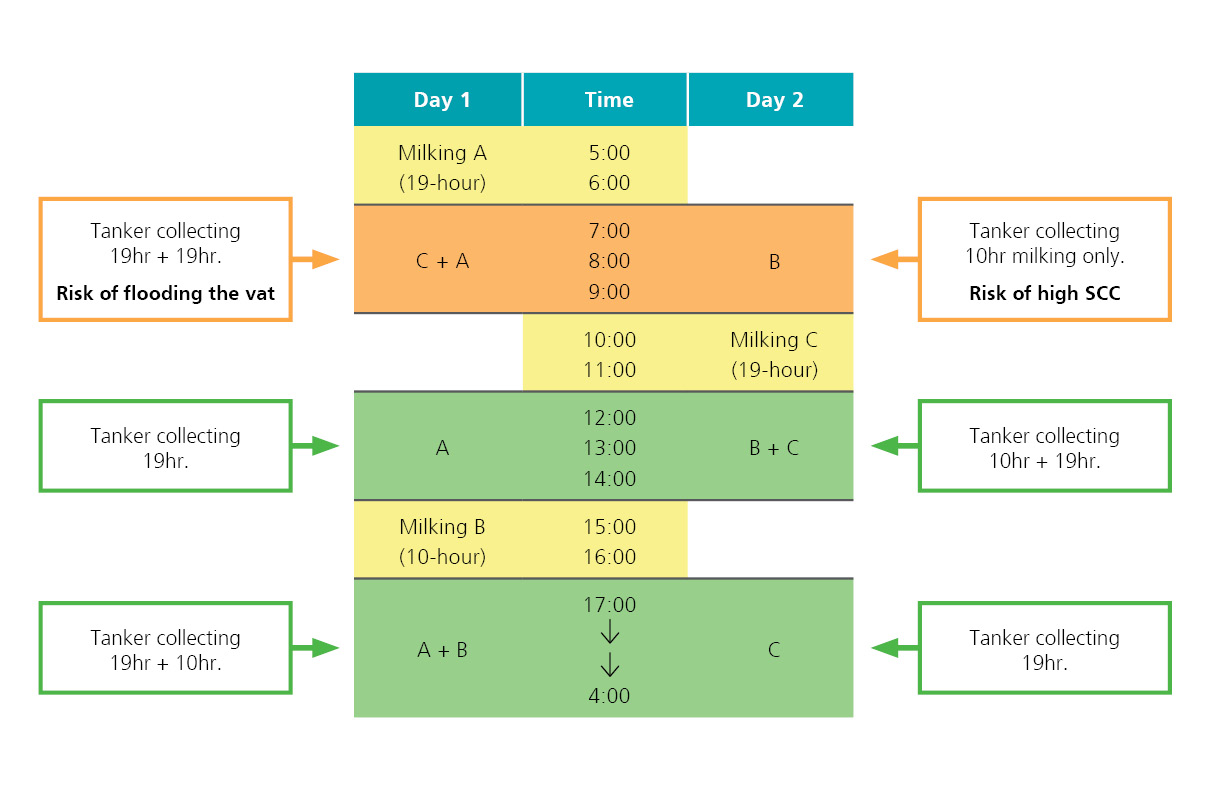

If you are on daily tanker pickups, work with your milk supply company to select the most suitable time for your pickups (see Figure 1).

If you are on skip-a-day pickups, then SCC of individual milkings will not come into play, as every pickup will have all three milkings.

Figure 1: Diagram showing tanker scheduling options assuming a daily pickup and the tanker coming in the same window each day for a 10-19-19 system.

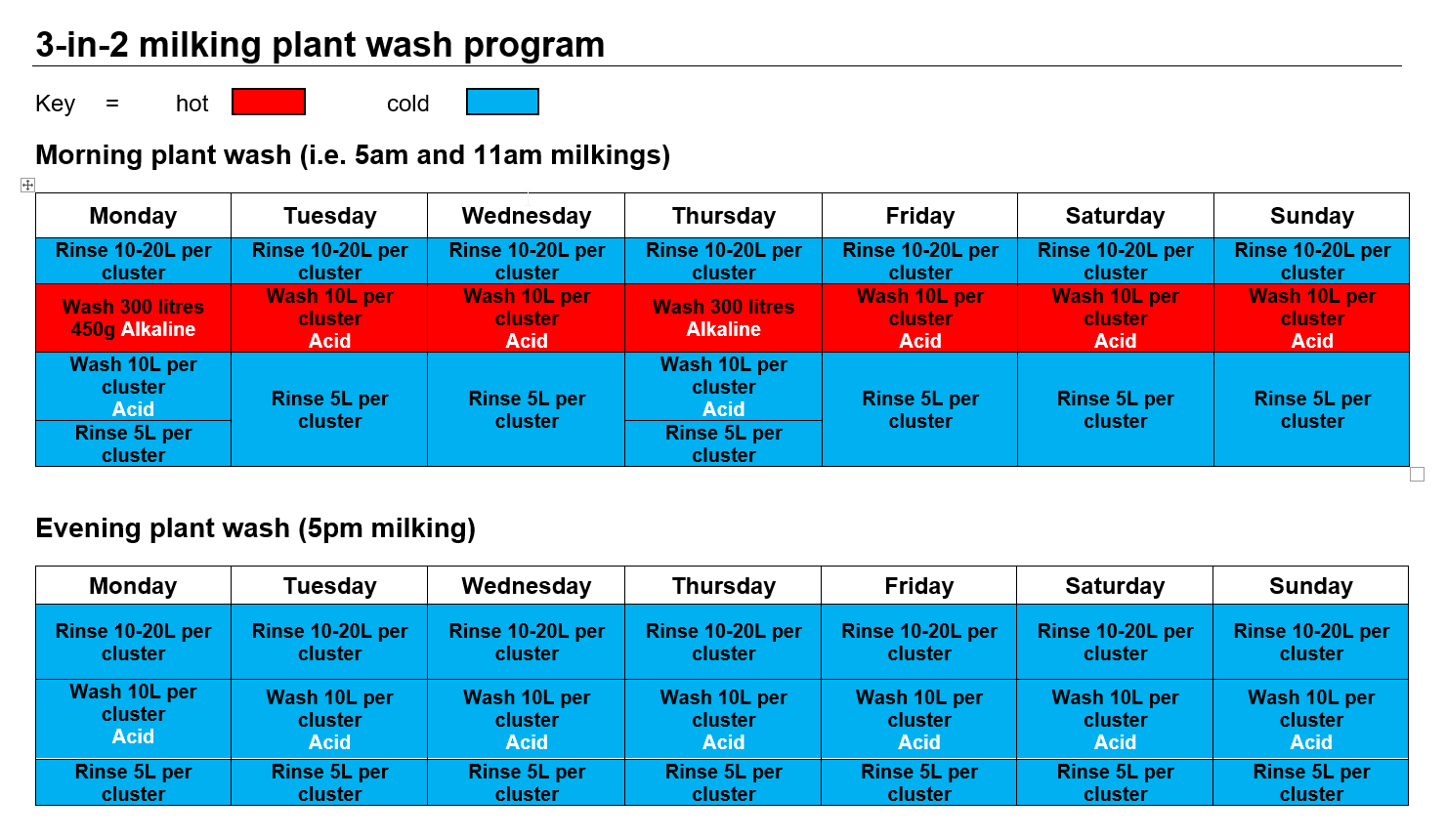

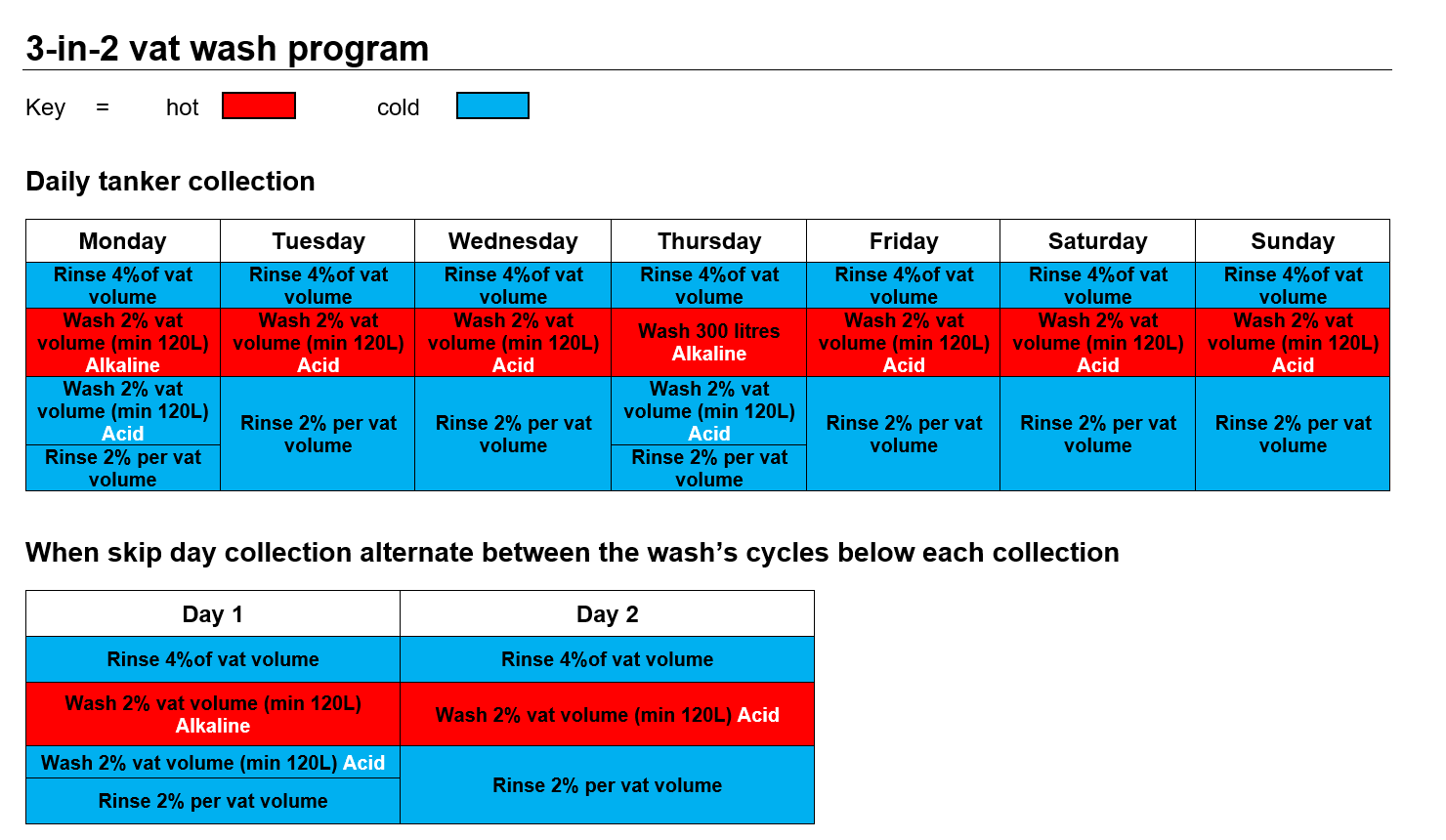

Adapting the plant wash programme for 3-in-2

The following are example plant and vat cleaning schedules for 3-in-2 milking. Consult with your dairy detergent supplier to discuss the most suitable programme for your plant.

Plant wash example:

Vat wash example:

Mastitis treatment under a 3-in-2 milking regime

It is likely that any mastitis treatments administered under 3-in-2 milking regimes would be considered as going 'off-label' due to treatment intervals. Off-label use of any product has a default milk withholding of 35 days.

Not getting vet approval or following the 35 day withholding would likely breach the conditions of supply with your milk processing company or the overarching regulations in NZCPI (MPI regulations for milk supply for human consumption in NZ). Therefore, it is important to discuss your options and withholding periods with your vet and get the required sign-off to be using the treatments under your new regime.

Things you should discuss with your vet to select the most appropriate treatment and get sign off include:

Hear how Jon Totty has managed mating in a 10-in-7 system.

Video 2:27 min

Hear from Taranaki farmers Daryl and Karyn on handling mastitis.

What prompted the Lincoln University Demonstration Dairy Farm’s move to full-season 10-in-7 milking? And what impact has it had on animal health, fertility, production and staff wellbeing? We speak with demonstration lead Jeremy Savage. Also on the episode is DairyNZ scientist Paul Edwards, who shares what the research is telling us about the effect of different milking intervals on milk production, fat and protein yields, and even sleeping patterns for farm staff.

Could reducing the number of milkings in a week help the dairy sector attract new staff and improve work-life balance? One farmer who’s gone to a flexible milking schedule is John Totty in Canterbury, currently starting his second full season milking 10 times in 7 days. What were his reasons for changing his milking schedule, and what kind of outcomes is he seeing?

This page was created by the Flexible Milking Project. This project is co-funded by NZ dairy farmers through DairyNZ and MPI through the Sustainable Farming Fund.