Herringbone bail pit

4 min read

The design of the milking bail, pipework, and pit in dairy farming is crucial for the safety and comfort of both cows and workers. This page outlines ways to ensure optimal cow flow and worker efficiency in the milking process. Key aspects include proper angles for milking positions, the use of zig-zag rump rails, specific design considerations for the first bail and pit wall, and guidelines for pit dimensions. By paying attention to these details, you can reduce animal health costs, increase worker safety, and lower injury risks, resulting in a more productive and humane dairy operation.

The design of the milking bail, pipework and pit is an important factor in keeping cows and people safe and ensuring good cow flow.

Benefits of getting it right include decreased animal health costs, increased worker safety and comfort, and decreased injuries.

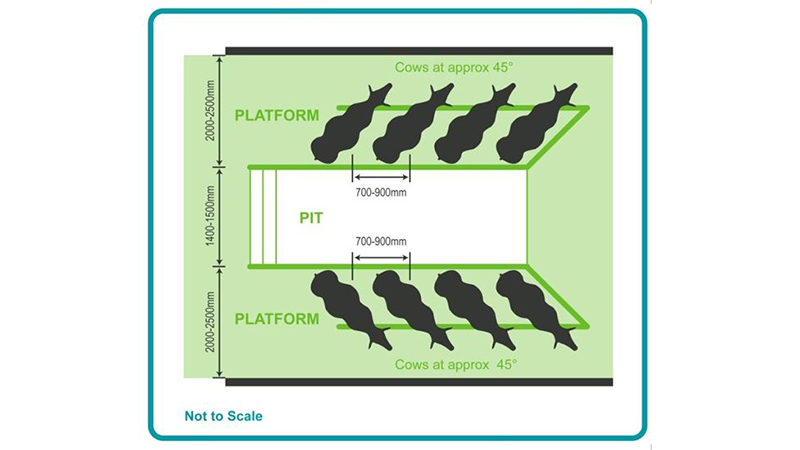

The angle cows stand on the milking platform at determines how much width each milking position requires.

For optimum cow flow:

Breast rail is too high, disrupting cow flow and preventing cows from rowing up properly.

Cow spacing on a herringbone platform.

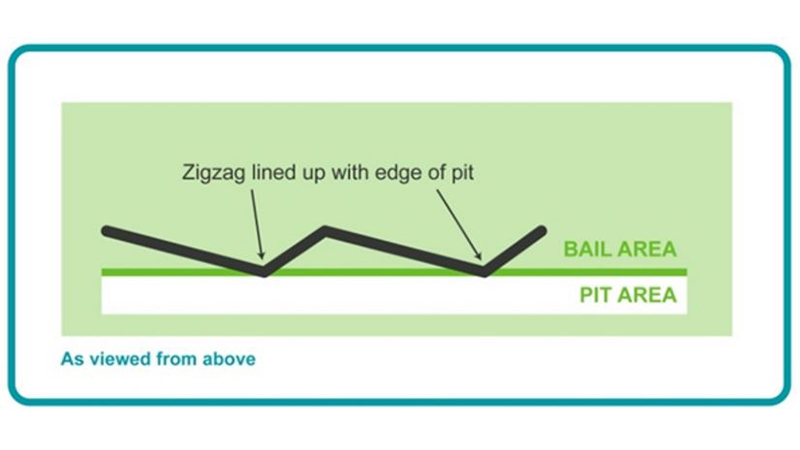

Zig-zag rump rails are a recommended alternative to straight rails and are designed to control the cow’s position and alignment with the cluster. The aim is to produce a faster, more even milking, and better cow flow.

The zig-zag rump rails help by stopping cows getting too close to the pit edge and stepping back into space, which can be a frightening experience for them.

For zig-zag rump rails to work well

A zig-zag rump rail will help cow alignment. Make sure it is in line with the edge of the pit.

Zig-zag rump rails.

The design of the first bail in herringbone dairies has an important effect on cow flow. If uncomfortable, cows will not want to be the first to enter the dairy. It is also the point of exit from the dairy, so needs to be designed to allow an easy exit.

Keep the following points in mind

Uncomfortable first bail, also obstructs exiting.

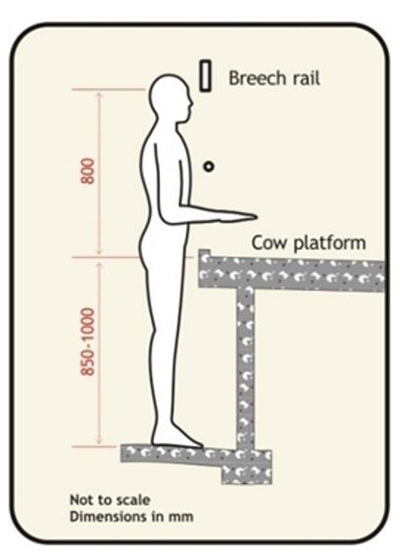

Key herringbone measurements.

A nib along the edge of the pit stops cows slipping into the pit and is essential with straight rump rails. One slip can make a cow nervous for future milkings. Keep the following points in mind:

If a nib is too high it can interfere with cluster placement.

Cows walking off-centre because no nib installed.

The pit is the area of the dairy where milkers spend most of their time and should be designed for milker comfort, safety and ease of movement.

In general, pits are between 850mm to 1000mm deep.

Pits are generally 1400mm–1800mm wide.

The surface and slope of the pit floor has a big influence on how tired those working in the dairy will feel at the end of milking. The pit floor drainage can be an OSH issue.

Pit dimensions diagram.